Friday, December 07, 2012

Technical Support & Ongoing Development

Our European Technical centre offers full support & service for all our customer’s technical requirements. At Rushden we have a fully equipped laboratory that enables us to perform testing on our customer’s own substrates. This is an important element during the adhesive selection process as there are many potential variations in substrates and surface chemistries.

Typical testing includes Lap Shear, Cleavage Peel and Charpy Impact which can be tested under control conditions, at various temperatures and humidity.

Running alongside the Technical Centre is the European R & D department, providing continuous improvements to existing products and new groundbreaking product developments. Our R & D not only ensures ITW Plexus is at the forefront of the latest industry developments it also makes sure our customers benefit from superior range of products to cover all their needs.

For any Technical enquiry please do not hesitate to contact the Technical Department -

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Advice | (0)

Comments •

Permalink

Tuesday, November 20, 2012

Overview of Adhesive Systems

By definition an adhesive is a substance, typically liquid or semi-liquid, which is capable of holding materials together by means of surface attraction. Surface attraction results from placing a thin layer of adhesive between 2 objects.

There are number of different types of adhesive available. The following list consists of the main types including some of their strengths and weaknesses.

Hot Melts

Advantages:

Good gap fill, versatile formulations, fast setting

Limitations:

Typically low strength, poor wetting, poor creep resistance, usually low solvent & heat resistance, special dispensing equipment required.

Silicones

Advantages:

Good gap fill, good for bonding glass, excellent sealant for low stress applications, excellent temperature resistance, flexible.

Limitations:

Low strength, limited solvent resistance, too flexible for structural loads, odour when curing, most require moisture to cure, slow curing.

Urethanes

Advantages:

Excellent toughness & flexibility, varying cure times, good flexibility at low temperatures.

Limitations:

Poor temperature resistance, sensitive to moisture (cured & uncured states), toxicity, short pot life, require special equipment to mix & dispense

Epoxies

Advantages:

High strength, can be filled with metals, versatile, wide range of formulations, good temperature & solvent resistance.

Limitations:

2 Component varieties require exact mixing ratios for optimal strength, one component products usually require refrigeration & heat cure, short pot life, slower fixturing, special equipment needed to weigh, mix & dispense.

Anaerobics

Advantages:

High strength (on some substrates), rapid cure at room temperature, good solvent & temperature resistance, versatile, non-toxic, easily automated.

Limitations:

Limited gap cure, won’t cure where air contact adhesive (wet fillets), primers required for many materials, 150-200C temperature limitations, generally brittle.

Cyanoacrylates

Advantages:

Rapid cure at room temperature, single component, excellent adhesion to rubber, high tensile strength, no mixing required, indefinite pot life.

Limitations:

Limited gap cure, low solvent & temperature resistance, poor impact & peel resistance, no water, chemical or environmental resistance.

Methacrylates

Advantage:

Good gap fill, excellent impact resistance, excellent peel & shear strengths, substrate versatility, medium / fast cure, tolerant to dirty surfaces, can be dispensed from most packages.

Limitations:

Some odour problems, flammable.

Please note that this is a generic list and the points listed are typical for the types but will vary between brands.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

| (0)

Comments •

Permalink

Tuesday, November 13, 2012

Diary of a Graduate: Katie Pepper

I have joined ITW Performance Polymers Europe (PPE) as a R&D Placement Student, taking a year out from studying Chemistry at Aston University in Birmingham. I am originally from a little village in the Peak District and have moved to Northampton for the duration of the placement year. Outside of work my hobbies include playing Gaelic football and skiing.

I will continually be updating my diary blog with my time at ITW PPE, but for the first few weeks’ here’s a quick run through…

My first week start as expected, a tour of the facility - office, laboratory and warehouse including introductions to the staff. I was then set up to carry out some E-Learning courses, so I could gain further understanding of the ethos of the company, and finished of the week with training on the Plexus, Devcon and Korroflex ranges and how to deal with customer queries.

My visit to our manufacturing facility in Shannon, Ireland was interesting with a tour of the site from the Chemical Process Engineer and introductions to staff in production. Whilst in Shannon I also meet the team from the ITW Wind Group and given an overview of products and service they provide.

Back in the UK I spent time with the various departments within ITW PPE from Customer Services to Accounts to understand how all aspects of the business come together. There is a lot to learn and look forward to the year ahead and the challenges it will bring with it.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

People | (0)

Comments •

Permalink

Sunday, November 11, 2012

Meet the Technical Department

Meet the experts…the Technical Department here at ITW Performance Polymers Europe (PPE), is a resourceful and experienced team, always on hand to support and offer advice. Here’s the chance to meet the team of four that will help you with your projects.

Dr Matt Savage

Technical Manager

After graduating from Loughborough University with a PhD in Polymer Chemistry, I have continuously worked within the adhesives industry, supporting the Automotive OEM’s and Tier 1 suppliers as well Truck & Bus manufacturers. I have held roles as diverse as R&D Chemist, Technical Support Chemist and Technical Sales prior to my current role as Technical Manager for ITW Plexus. My background in a wide range of adhesive technologies and applications means that I am able to support your technical enquiry no matter how unique.

George Green

Technical Support Engineer

I started working in the Technical Department at ITW PPE 5 years ago following graduation from an Earth Science Degree. The best part of my job is visiting customer sites to discuss the test work I have completed and talking through the results and recommendations. My role is varied, I can be found in the lab conducting test work for projects submitted by the Sales Team, handling enquiries, researching or supporting future development projects.

Tom McNally

Product Support Technician

Since leaving school, I have worked as a Laboratory Technician for a specialist analytical testing company. After spending almost 3 years testing consumer products (shoes, gloves, personal protective equipment etc.) for chemical due diligence I moved to ITW. In the year I have been with ITW, I have been integral in a wide range of projects, testing and also manning the Technical helpdesk, acting as your point of contact for both adhesives and MRO products. This experience means I can assist you with any technical enquiries you may have.

Katie Pepper

R&D Placement Student

I joined ITW in September as a placement student as part of my Chemistry degree with Aston University. My main focus will be with the R&D team, both in Europe and the USA, working on developing unique high performance products.

As a team we offer a wealth of experience and knowledge from a diverse range of backgrounds and we look forward to working with you on your projects to ensure that you select the best possible materials and have the confidence to use them.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

People | (0) Comments • Permalink

Friday, November 02, 2012

Surface Preparation - Metals

Metals typically require some surface preparation prior to bonding with most adhesives in order to improve adhesion.

Degreasing the metal surface is essential in order to remove any oil or grease. If this is not removed it can prevent a good adhesive bond. Cleaning after any surface treatment is also important as any excess residue or debris on the surface will again affect the adhesive bond strength.

The main methods of metal surface preparation are:

1. Solvent cleaning – A solvent is applied to the surface to dissolve the contaminate material. This can be accomplished by a Solvent dip, Solvent wipe, Vapour degreasing or Ultrasonic Cleaning.

2. Chemical cleaning – More severe than solvent cleaning, chemical cleaning removes contaminants from the surface by harsh chemicals. Hot Alkaline Cleaning, Pickling & Etching are three types of Chemical Cleaning.

3. Conversion – Surface cleaning through a conversion process changes the original surface into a new material. Three types of conversion are Phosphating, Chromating & Anodizing.

4. Priming – Some adhesives require a primer to be applied prior to bonding.

5. Abrasion – Light abrasion of the surface gives a better key to the adhesive than a high polish. Freshly abraded surfaces usually are better for achieving good bond strength. Brushing & Blasting are the most common methods.

When bonding stainless steel or aluminium in the laboratory ITW Plexus typically cleans the surfaces with acetone and applies a thin film of PC120 primer/conditioner (except when using MA830 and MA832). PC120 is a primer/conditioner designed to improve the long term durability of Plexus adhesives when used for adhering aluminium and stainless steel assemblies.

Please note that this is a general guide to surface preparations used in the market. Due to many potential variations in substrates and surface chemistries, ITW Plexus strongly recommends all substrates be tested with selected adhesive in the anticipated service conditions to determine suitability.

Please contact our Technical Department at

if you have any questions.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Advice | (0) Comments • Permalink

Friday, October 19, 2012

Adhesives V Traditional Methods – Metals

Adhesives are an alternative method of joining metals. Traditional methods include welding, soldering, riveting, nut & bolts.

What do adhesives offer over the more traditional methods?

1. Ease of use – no specialised training

2. Cosmetic appearance – smooth surface contour

3. Speed – can reduce labour time

4. Bond dissimilar materials - such as metals to composite or plastic

5. Stresses distributed over a wider area – low stress concentrations

6. Lighter weight – reducing the weight of the final assembly

7. Seal against corrosion and adhesive will not corrode

8. Excellent fatigue properties

The advantages listed are based on Plexus adhesives and will vary between the different adhesive technologies available.

ITW Plexus offer a wide range of adhesive bonding solutions for a number of industry applications.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Advice | (0)

Comments •

Permalink

Monday, October 08, 2012

ITW World Environment Week

This year saw the first ITW World Environment Week take place between 4th— 8th June in Shannon, Ireland. The focus of the week was based on energy and the slogan issued was ‘Preservation for Conservation’. As part of commitment to this week, the Environment and ISO14001, ITW Performance Polymers Europe took the opportunity to raise and promote energy awareness amongst the staff by carrying out a few simple actions;

Energy Awareness Campaign

a) Switch off everyday email campaign. The focus of the email campaign was to draw attention to equipment that may be left on and draw energy unnecessarily overnight.

b) Posting interesting energy facts on the notice board and making them available on tables in the canteen. Information that was posted was designed to be informative and raise people’s interest in the area of energy and energy awareness. Information was updated during the week to keep it fresh so that it would become a ‘talking’ point over the week.

• Poster Competition

c) A poster competition was held where active participation from family members was strongly encouraged.

Poster competition entries received above.

Congratulations to the winners

1st Place: Fergal Ginnane (Fintan Ginnane)

2nd Place:Brian McNulty (c/o Noreen O’Neill)

3rd Place: Eimear Ryan (c/o Kay O’Gorman)

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

People | (0)

Comments •

Permalink

Friday, September 28, 2012

A New Record

Congratulations to Eng. Buzzi and his team for completing the Bermuda Challenge in a record 17 hours with an average speed of 46 knots 52 mph.

.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Events | (0) Comments • Permalink

Friday, September 28, 2012

The Bermuda Challenge

“The Bermuda Challenge” is as the title suggests, an endurance trial set for powerboats to travel from New York to Bermuda, some 673nm (774 miles) in the shortest time possible. This is not a competition in which many boats compete together side by side, but a challenge which needs many months of preparation and organisation, not least because the event normally takes place in the summer months where the weather conditions are unpredictable.

The current record time is held by Chris Fertig, who recently managed to beat the existing record achieved in 2002, shaving 44 minutes off the time. The challenge was completed in just under 22 hours, no small feat for a powerboat on the open sea.

Fabio Buzzi from FB Designs is a well-known and respected boat builder based in Italy. FB Designs build high speed interceptor boats for military and civilian coast guard use. ITW Plexus has been supplying FB Design with structural adhesives to use on various applications on the vessel, allowing Eng. Buzzi and his design team to develop revolutionary concepts in boat building.

The Bermuda Challenge started last night in New York at 17:00 with Eng Buzzi predicated to arrive in Bermuda app. 19:00 this evening smashing the existing record, with an average speed of 48 Knots (55 mph or 88 kph).

You can track the team’s progress at http://fbdesign.it/record.php

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Events | (0)

Comments •

Permalink

Friday, September 21, 2012

Reporting from the Innotrans Exhibition

Hello to everyone from the Innotrans exhibition. This is my first blog post, and for those of you who I have yet to meet, I am Thorsten Petersen the newly appointed Territory Sales Manager for Germany and Switzerland.

Day three of the show and today Sally Sinai (Product Manager) and I approached the big unions of Railway suppliers and Railway companies in Europe. The objective is to build a relationship with these associations with a view to being involved in their design process. Also introduced ourselves to various composite, interior, carpet and head light manufacturers.

My summary from the biggest rail show is that in future we should be present here with a coordinated ITW stand including MRO, Fasteners and Automotive, demonstrating our wide range of competence.

Closing with the sentence of today: “There are no problems, there are only projects.”

Good bye from Berlin for now.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Events | (0)

Comments •

Permalink

Wednesday, August 29, 2012

ITW Plexus exhibit at Innotrans 2012 in Hall 2.2, Stand no. 215/L

ITW Plexus will be exhibiting for the first time at the Innotrans exhibition in Berlin, sharing space on the UK Trade and Investment stand.

Sally Sinai (Product Manager) and Thorsten Peterson (Territory Sales Manager) will be present throughout the show to discuss the benefits and savings ITW Plexus structural adhesive technologies can offer manufacturers and suppliers into the rail industry.

For those not familiar with ITW Plexus, we have been supplying into the Rail Industry for a number of years, and have worked with manufacturers on applications such as bonding floors, roof fairings, cab mouldings, draught screens and stand backs amongst many others. What’s more, our adhesives are used not only to speed up production, reduce component weight and increase durability but to also achieve aerodynamic efficiency and improve the aesthetic finish of the component.

So, if you’re planning on a visit, be sure to stop by our stand and see Sally & Thorsten.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Events | (0)

Comments •

Permalink

Friday, May 04, 2012

European Plexus Manufacturing Facility Update – Process Control

Focus on Process Control

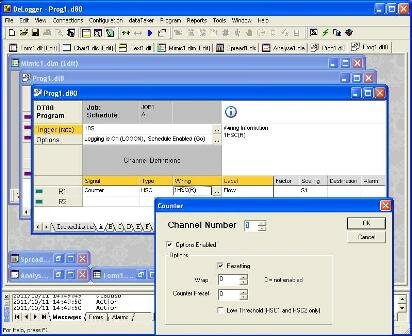

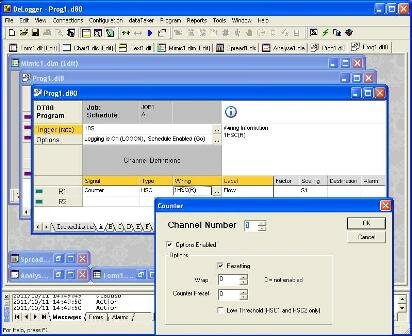

Hello again from the Plexus manufacturing team, here in Shannon. I would like to talk more about the Plexus manufacturing practices & the process control mechanisms implemented during an average day of production. The production of the Plexus 1:1 adhesives & activators is a complex and involved process but certain mechanisms of the process in particular require specific attention due to their critical nature. These mechanisms have been identified as Critical Process Parameters or CPP’s & they are labelled as such in the batch record. By using the CPP’s as a procedural tool it not only informs the Operator but it also gives the Operator a better understanding of the process & indeed the products themselves.

The CPP’s ultimately highlight functions of the manufacturing process both physical & chemical; which may impact the overall quality of the product. Using these CPP’s as a lead, we have installed a Datalogging system which monitors product temperature, vessel pressures & mixer blade RPM speeds – all CPP’s.

The dataTakker – Delogger Version 5 has been installed to give greater control of the manufacturing process & as an instrument in maintaining the production of a high quality product.

.bmp)

The data collected can be used to trend the process parameters & analyses product behaviour; data which can be used for qualitative & quantitative process improvements. The dataTakker – Delogger Version 5 also has an online facility which allows for remote monitoring of the process via the internet from anywhere in the plant or indeed the world!

In addition all process scales & balances are also logged. All weights of raw materials & final product are logged using software supplied by Avery Weigh Tronix. Again, this gives us instant process data which is critical to final product quality & greater stock control.

Posted by PaulColes , Chemical Process Engineer, Shannon, County Clare, Ireland

| (0)

Comments •

Permalink

Tuesday, April 17, 2012

Anixter wins ITW Plexus 2011 Distributor of the Year Award.

ITW Plexus presents Anixter with 2011 Distributor of the Year Award and Steve Maw, Commercial Director for Anixter tells us what it means to receive the award.

ITW Plexus’s annual award for “Distributor of the Year” is presented to Anixter in recognition of their outstanding achievement over the course of the year. ITW Plexus Business Development Manager Chris Coll told us “This award reflects the hard work and positivity that Anixter brought to the partnership in 2011 - and they continue to bring each and every year. Anixter’s proactive approach and excellent customer service have brought consistent year on year sales growth and it gave me great pleasure to reward their endeavour with the Plexus Distributor of the Year title”.

The award was presented to Steve Maw, Anixter’s Commercial Director, on Monday 19th March 2012, at Plexus’ UK headquarters in Rushden, Northamptonshire. Steve Maw was understandably delighted to receive the award and said “Our partnerships with leading manufacturers are essential to Anixter’s success and we are proud to have been awarded ITW Plexus’ European distributor of the year. It is testament to the joint strategy of introducing product innovation and enhancements to manufacturing processes in the industrial market sector that has created a successful partnership. The partnership principles have created a relationship that is at the forefront of technological advancement in the adhesive industry. Adhesive application engineering creates a competitive advantage for the partnership as industry welcomes new opportunities to grow and expand its knowledge whilst increasing its profitability.”

Once again, I would like to thank Anixter for making 2011 a successful year for us all and hope we can do the same for 2012!

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

| (0) Comments • Permalink

Monday, March 26, 2012

ITW WindGroup exhibit at JEC 2012 on stand no. K65

The global team of ITW WindGroup and ITW Plexus will be exhibiting at this year’s JEC show, commencing on 27th March and running until 29th March 2012 in Paris, France.

The ITW WindGroup team members that will be attending include; General Manager, Mark Feist, Sales Manager of North and South America, Pat Shannon, Asia Sales Manager,Tony Zhang, India Sales Manager, Swaroop, Business Development Manager for Europe, Peter Gorlitz and the Sales Manager for Europe, Erwin De Leeuw.

The ITW Plexus Europe team will also be attending to offer visitors information and advice regarding our structural adhesives. Mike Howard, Kevin Lacey, Sally Sinai, Alex Grazia, Floris Somers, Jean-Charles Pucheu and Chris Coll will all be available throughout the show, so feel free to have a chat with them.

The JEC show is the most popular composites show that supports the development of composite materials by fostering knowledge transfer and exchange between suppliers and end users. The JEC show expects around 250,000 professionals from around the world. Let us know what you thought of ITW Wind Group and ITW Plexus at the JEC.

The ITW WindGroup is a global supplier of a diverse portfolio of products for composite fabrication, foundation and construction, and operations and maintenance for the demanding needs of the wind turbine manufacturing. The company brings to the wind industry tailored solutions through such engineered products like adhesives, sealants, foundation systems, vacuum bag tapes, tower & blade coatings, anti-skid coatings, cleaners & degreasers, mold release, grease, lubricants, tapes, mechanical testing equipment helping its customers achieve exceptional quality results through highly engineered chemistries, process improvements and cost savings. The ITW WindGroup has strategic management teams located in North & South America, Europe, and Asia. Each team, along with their distribution partners, can provide local support anywhere in the world.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

| (0)

Comments •

Permalink

Friday, February 03, 2012

Adhesive Groups

The list below provides a brief summary of the adhesive groups.

Heat-Cured Adhesives:

These include any adhesives which must be heated to promote curing.

Holding Adhesives:

Holding adhesives are used to hold surfaces together, but not permanently. They do not have to withstand a great deal of force. Adhesive tape is a good example of a holding adhesive.

Hot Melt Adhesives:

Hot melt adhesives are applied in the molten state and then harden. The adhesive substance is melted, applied to the surface, and then the parts are joined. Once the adhesive cools and solidifies, the joint is complete.

Instant Adhesives:

These include any adhesives that cure within seconds to minutes such as a Cyanoacrylate Adhesive.

Locking Adhesives:

Locking adhesives or sealants are used to prevent the loosening of threaded parts. Locking adhesives are placed on the threads of a bolt to prevent it from becoming loose from vibration.

Pressure Sensitive Adhesives:

Pressure sensitive adhesives form bonds easily when pressure is applied. Pressure sensitive adhesives are used on items such as self-sealing envelopes and double-sided tape. The joint is made with very little pressure.

Retaining Adhesives:

Retaining adhesives are very similar to locking adhesives however they are used on non-threaded parts to prevent twisting or sliding.

Sealing Adhesives:

Sealing adhesives are used to prevent the passage of air, water, oil etc between two surfaces. An example is the caulking around windows.

Structural Adhesives:

Structural adhesives are capable of withstanding a significant load. The term ‘significant load’ implies that the adhesive must be able to with stand a great deal of stress. In fact, it could be said that in the absence of unnaturally high forces, the substrates could be considered to be permanently joined.

Ultraviolet Adhesives:

Any adhesives that cure when exposed to UV light.

Posted by Abarmettler, ,

•

Advice | (1)

Comments •

Permalink

.bmp)