Thursday, December 08, 2011

European Plexus Manufacturing Facility

Introduction to Shannon MMA Manufacturing Facility

Hi All, I’m pleased to announce the commencement of the production of Plexus Structural Adhesives at our facility in Shannon, Ireland. We are currently producing the MA300 & MA310 1:1 adhesives & activator for both the European & Asian market.

Previously the products were manufactured in the US at our plant in Danvers, MA & shipped to Shannon to be down packed to pails & cartridges for our European & Asian customer base. The filling operation will remain the same but the manufacturing facility has given us improved stock control mechanisms, especially crucial for the short shelf life products & this mechanism will enhance product quality & further product development. All this will be beneficial to our customers as it will allow us to have greater reactivity to customer demands & greater control of the product quality.

The manufacturing facility is also of benefit to our ISO14001 Environmental Management Certification. As we no longer import these products from the US & we source raw materials in the EU reducing our carbon footprint. These practices help build a more environmentally sustainable business model.

It will be our intention to expand & develop our Plexus product portfolio & eventually become self sufficient but until then our European & Asian customers can expect consistency from the European Plexus Manufacturing Facility in both product & service.

Posted by PaulColes , Chemical Process Engineer, Shannon, County Clare, Ireland

| (0) Comments • Permalink

Friday, November 18, 2011

New Transportation Brochure.

It’s been 8 months since the launch of our much anticipated Transportation Brochure, so what is the feedback?

“Great!“ and “something we should have done 10 years ago” was the feedback we received from customers and distributors across Europe. Not a bad review for a first document, kudos to those involved! It was designed to be user friendly and informative, and it seems to tick both of those boxes. We can definitely see there is demand for more of these documents, so watch this space for future editions….

Posted by Abarmettler, ,

| (1) Comments • Permalink

Tuesday, November 08, 2011

Joint Stress Distribution

Joint stress distribution is the location of stresses within a bond.

Tension and Compressive Stress Distribution:

When a bond experiences either tensile or compressive stress, the joint distribution is illustrated as a straight line. The stress is evenly distributed across the entire bond.

Shear Stress Distribution:

Shear stresses are distributed across the bond in an entirely different way. The ends of the bond resist a greater amount of stress than the middle of the bond does.

Cleavage and Peel Stress Distribution:

When cleavage or peel stress is applied to a joint, most of the stress is concentrated at one end.

Posted by Abarmettler, ,

•

Advice | (0) Comments • Permalink

Tuesday, October 18, 2011

Types of Stress

What is stress?

Stress is a force applied to a bond, usually expressed in N/mm2 (Newton’s per square millimetre) or MPa (Mega Pascals).

The following types of stress are commonly found in adhesive bonds:

1. Impact Stress – this occurs when a sudden force or shock is applied to a joint.

2. Tensile Stress – tensile stress tends to pull an object apart. It also tends to elongate an object.

3. Compressive Stress – The opposite of tensile stress, compressive stress tends to squeeze an object together.

4. Shear Stress – this stress is created by two surfaces sliding over one another.

5. Cleavage Stress – occurs when a joint is being opened at one end

6. Peel Stress – peel stress occurs when a flexible substrate is being lifted or peeled from the other substrate.

Posted by Abarmettler, ,

•

Advice | (0) Comments • Permalink

Friday, October 14, 2011

Plexus launches Italian website

Plexus website now available in Italian.

Our new Italian website is officially up and running! Take a look at: https://itwplexus.co.uk/index.php?/Italian/

Take a look and let us know what you think.

Posted by Abarmettler, ,

•

Company News | (0) Comments • Permalink

Wednesday, September 28, 2011

Types of Joints

A Joint is the location where an adhesive joins two substrates. The Geometry of a joint refers to the general shape of an adhesive bond.

The two main factors to consider when designing a joint for adhesives are the strength and aesthetics.

Typical joint designs:

Lap/Overlap Joint - A lap joint, also known as an Overlap joint, is formed by placing one substrate partially over another substrate.

Joggle Lap Joint - A joggle lap joint is an offset joint very similar to the lap joint.

Double Lap Joint - A double lap joint incorporates two lap shear joints in one.

Butt Joint - A butt joint is formed by bonding two objects end to end.

Scarf Joint - A scarf joint is an angular butt joint. Cutting the joint at an angle increases the surface area.

Strap Joint - The strap Joint is a combination overlap joint with a butt joint. There are single and double strap joints.

Cylindrical Joint - A cylindrical joint uses a butt joint to join two cylindrical objects.

Biscuit Lid Joint – The biscuit lid joint is a variation of a joggle lap joint

Toggle Joint - A toggle joint is formed by fitting the two substrates together in a ‘tongue and groove’ type formation.

Stepped Lap Joint - This is a variation of a lap shear joint.

Flange Joint - This is a variation of an Overlap Joint.

Posted by Abarmettler, ,

•

Advice | (0) Comments • Permalink

Thursday, June 30, 2011

Changes within the ITW Plexus Business

ITW Plexus has recently undergone some changes within its structure, which includes;

Kevin Lacey’s promotion to the new position of ITW Plexus Business Manager. Kevin has worked with ITW Plexus for the past 10 years and brings with him a wealth of knowledge and experience of the adhesives industry to the position. Commenting on his appointment as Business Manager, Kevin said ‘I am delighted to have the opportunity to build and develop the business to the next level throughout Europe and ROW. I am excited about the opportunities we have and feel fully equipped to meet the challenges we will face growing the business with a strong and dedicated team’.

In addition to the change in management, ITW Plexus has appointed two new members: Michael Reynolds who has joined the company as a Business Development Manager. Mick will be responsible for both the Solid Surfacing and Sta-Put businesses. Also, Zafer Apaydin has recently joined ITW Plexus team as the new Sales Manager looking after the Turkish market.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

People | (2) Comments • Permalink

Tuesday, June 14, 2011

REACH Update

ITW Plexus is pleased to announce that all substances found in its adhesives have now been successfully pre-registered under the REACH legislation.

Performance Polymers Europe (PPE) has also completed a number of substance registrations in 2010 ahead of the first REACH registration deadline and is now focused on 2013 and 2018 registration deadline substances. The PPE REACH Coordinator is thoroughly following all new developments on REACH and will evaluate the impact on ITW Plexus adhesives. PPE is committed to complying with the REACH Regulation to provide greater responsibility to industry and to manage the risks from chemicals and to provide safety information on the substances used in all member company products.

PPE has also completed the Classification, Labelling and Packaging of Substances and Mixtures (CLP) notifications for close to 1000 substances both for itself and on behalf of EU based customers importing product directly from the US. These CLP notifications have been completed for ITW Plexus and submission reports are available to customers upon request. PPE are monitoring the use and import of all new substances and CLP notifications are being submitted on an ongoing basis.

For more information visit http://www.itwppe.eu/index.php?/ppe/internal/sustainability/, alternatively you can contact Jason Brogan, REACH Co-coordinator on

for more information.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Advice | (0) Comments • Permalink

Friday, May 06, 2011

2010 ITW Plexus Distributor of the Year awarded to Vaber Industriale

It was my pleasure to present Alberto Bettini from Vaber Industriale with the ‘Distributor of the Year’ award. It has been well deserved, as all the members of staff at Vaber including the sales team, customer services, technical support and warehouse workers have done an extremely good job in managing and distributing Plexus adhesives throughout Italy.

Vaber Industriale has been a strategic distributor partner with ITW Plexus for over ten years and has consistently grown its performances year on year.

Vaber has achieved this success due to its understanding and knowledge of Plexus, coupled with its route to market - Vaber strives to help customers find value added solutions, they support customers on a day to a day basis and offer a highly professional and skilled service on a daily basis.

As the Territory Manager for South East Europe, I have had the pleasure of working closely with Alberto Bettini, Alberto Del Panta and other key members of staff and can guarantee that Vaber still has the same enthusiasm and passion for selling Plexus as it did from the beginning.

Kevin Lacey and Paul Wright with the Vaber Industriale Team

Once again, I would like to thank everyone at Vaber for making 2010 such a successful year.

Posted by Paul Wright., Territory Manager, Italy

•

Company News | (0) Comments • Permalink

Monday, February 28, 2011

ITW Plexus exhibit at JEC Composites 2011, along with ITW WindGroup on Stand no J57

ITW Plexus will once again be exhibiting at JEC Composites in Paris and this year we will be sharing the stand with the newly formed wind energy group, known as ITW WindGroup

ITW Plexus will be highlighting the benefits and savings that major transportation, marine, automotive, wind energy and engineered construction manufacturers are achieving by using the company’s latest high performance range of methacrylate adhesives to bond many dissimilar materials.

The recently formed ITW WindGroup manufactures & supplies adhesives, tapes, sealants, foundation systems, coatings, and other solutions to the wind energy market. These products provide the wind industry with solutions for blade assembly, maintenance & repair, tower manufacturing & assembly, and nacelle & hub assembly. The Group has strategic management teams located in North & South America, Europe, and Asia and each team, along with their distribution partners, can provide local support anywhere in the world.

During the show the ITW WindGroup will be demonstrating a range of products which provide value to the production process of blades and other composite structures of the wind turbine and related field maintenance & operations. This range consists of tacky tapes, structural adhesives & sealants, blade cleaners, leading edge protection tapes & coatings and Teflon release films.

Staff from Plexus Europe and the ITW WindGroup will be available throughout the show on stand J57, to elaborate on the benefits and savings that their technology systems can offer distributors and major end users.

We look forward to seeing you there.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Events | (4) Comments • Permalink

Wednesday, November 24, 2010

Using PC-120 cleaner / Conditioner

PC-120 is generally used when there is a need for increased durability in the bonding application.

One of the little known qualities of PC-120 is that it not only improves the durability of key Plexus products but can also improve the durability performance of the special metal bonders MA830 and MA832.

PC-120 works by cleaning the surface of contamination using Isopropyl Alcohol (IPA) as a solvent to lift machining oils and other contaminants from the surface of the metal then leaving a thin phosphate based coating to retard surface corrosion.

To tell which areas have been primed, PC-120 leaves a pink colour on the surface. PC-120 can be brushed, wiped or sprayed onto the surface and can be wiped clean with a dry rag to leave a thin quick drying film.

Application tips!

1. Do not use too much PC-120 – Only a very thin coat is needed you should only see a very faint pink colour on the metal.

2. Do not use dirty or oily rags to apply PC-120 – Dirty rags will put contaminants onto the surface rather than removing them.

3. Remove any corrosion – Abrade any surface corrosion before applying the PC-120

4. Check the shelf life – Product which has exceeded its expiry date will not perform in specification.

5. Close the bottle – Open bottles allow the solvent to evaporate.

Posted by Abarmettler, ,

•

Product | (2) Comments • Permalink

Friday, October 01, 2010

InnoTrans Trade Show 21st - 24th Sept, 2010

Hello again everyone. Well, some of you may remember my blog last year from Seatec in Italy; here’s my latest one. I hope you enjoy it.

Last week I attended the InnoTrans Trade Show in Berlin in order to give some technical and commercial support to our Italian distributor – Vaber Industrial, who was exhibiting there for the first time.

This planned three day trip didn’t get off to the auspicious start I had hoped for as the flight to Berlin was delayed over four hours, which resulted in me missing most of the first day. I made up for this over the next couple of days and can safely say that my legs are still slightly wobbly from all that standing (anyone who’s participated at a trade show will know what I mean).

InnoTrans, for anyone not familiar with the name, is the world’s biggest trade show dedicated to the Rail Industry. Every facet was there, click onto the link for more information www.innotrans.com.

On my arrival at Innotrans, a number of things struck me, namely everything is vast. There were 25 Halls – all the size of football pitches or bigger. With a whacking 3.5km to cover I can understand why they laid on a bus shuttle service. With an entrance fee of €46 the organisers obviously targeted companies and individuals with a genuine interest in the rail industry and kept the students out.

Over the years, I have attended a number of trade shows, but I can quite honestly say that I have never seen so many visitors. Vaber’s stand, which was situation in an ideal location, had a steady stream of visitors all day, and needless to say the coffee machine was pumping espressos out at a high rate of knots. Our Italian visitors, who were from the biggest OEMs in Italy, were delighted they could drink “real” coffee.

So where, you may be asking, do structural adhesives fit into this industry? Well, many train manufactures see the benefits and advantages of using ITW Plexus as an alternative to traditional methods. A simple example, aluminium, because of its weight, strength and anti-corrosive properties is increasingly being used in carriage and wagon construction, both internally and externally.

There are two traditional ways to fix aluminium parts together – welding or mechanical fixing with nuts and bolts, screws or rivets. ITW Plexus on the other hand offers design engineers the possibility of joining, not only aluminium to aluminium, but different types of substrates together too (which is not possible with welding); this not only improves aesthetics by avoiding rivets and screw heads, but also offers high flexibility and fatigue resistance. This also helps to overcome the problem of joining two different materials which have different thermal expansion properties.

The trade show was truly an international exhibition; I spoke to visitors from South Korea, Japan, China, USA, and India (and that was just in the queue for the gents). All continents were represented and my feeling is that both Vaber and ITW Plexus had a very worthwhile and positive experience, with some goods leads and contacts made.

(L-R) Kevin Lacey, Alberto Del Panta, Silvia Salamone,

Alberto Bertini, Paul Wright & Chris Coll

Posted by Paul Wright., Territory Manager, Italy

•

Industry News | (0) Comments • Permalink

Thursday, September 23, 2010

E-RA reach the finals

The final results for the Progressive Insurance Automotive X PRIZE competition were published and the E-RA took an impressive second place in the alternative side-by-side class.

The competition started with 136 cars, of which only a few made it to the finals. There were several tests including technical inspection, acceleration/braking, lateral acceleration and dynamic safety. The E-RA successfully passed them all.

Congratulations to the RaceAbout team.

Find out more about the E-RA in the video released by Progressive Insurance Automotive X PRIZE.

Posted by Gurpreet Pawar, Marketing Executive, Rushden, UK

•

Industry News | (0) Comments • Permalink

Friday, September 10, 2010

ITW Plexus Approvals

We, at ITW Plexus recognise the importance of getting products approved by a professional body. This is why we continually strive to have our products recognised and certified by professional bodies which matter to customers, engineers and designers alike.

ITW Plexus has over the years achieved many approvals including Germanischer Lloyd, ABS and RINA (which we have recently achieved a re-approval). To familiarise you with the bodies, I’ve given you an overview of the industry they represent.

Germanischer Lloyd (GL)

A German based classification society that serves the energy and maritime sectors. GL offers Classification, Research, Assessment and Consultancy services.

American Bureau of Shipping (ABS)

Develops and validates standards of marine and off-shore design, construction and operational maintenance of facilities. As the name suggests this classification society was first chartered in New York State, USA.

Royal Institution of Naval Architects (RINA)

A world renowned, highly respected, professional organisation. RINA has members within many divisions including design, maintenance, construction and operation of all vessels and structures.

ABS and RINA are similar organisations given that they are both international, renowned bodies that are concerned with marine and off-shore facilities. ITW Plexus has approvals from both organisations’ for products as marine companies are inclined to have their own preference.

What are the benefits of getting approvals?

Comments received from various ITW Plexus employees and distributors with regards to the value of the approvals included:

‘Approvals offer quality assurance and recognition to the customer in the relevant industry’.

‘Customers within the energy and marine sectors look for adhesives and materials that have specific approvals’.

‘Approvals differentiate our products from our competitors. They also give customer’s the confidence that they are using a quality product for their application’.

Plexus product approvals:

MA530 - GL, ABS

MA560-1 - GL, ABS

MA590 - GL, ABS, RINA

MA425 - ABS

MA550 - ABS

MA556 - ABS, RINA

Posted by Abarmettler, ,

•

Advice | (4) Comments • Permalink

Tuesday, August 17, 2010

Factors that Influence Adhesion

Doesn’t it get you down when you stick something together; wait patiently for it to go off for it to all fall apart at your feet. Well help is at hand. Here are four key things that will stop an adhesive sticking

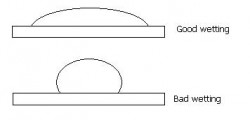

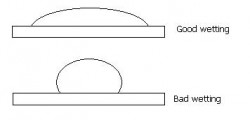

1. Wetting the surface

To get a good bond the glue needs to ‘wet’ the surface, i.e. spread out over the surface you want to bond. If this doesn’t happen, then you won’t get good contact between the glue and the material you want to join together. This wetting effect will be influenced by the materials you want to stick together.

If you’re unsure, the ITW Technical team can help you to find the best solution for your ‘sticky’ situation.

.

2. Surface treatment

The surface of the material you want to bond will make a big difference to how well your adhesive sticks. Contaminants such as grease and oil need to be cleaned off and some metals and plastics might need specialised mechanical or chemical treatment.

3. Structure of the material to be bonded

If you’ve got porous material, you need an adhesive that won’t be ‘absorbed’ into the structure and therefore leaving you nothing on the surface to stick to your other material. Choose a product which has a thick viscosity and it will stay where you put it with no sag or absorption.

4. Structure of the joint

To use an adhesive well the design of the joint is very important. Most adhesives need a good surface area to apply the glue on, the smaller the area the less of a load the part can withstand. Bonded joints are vulnerable to peel so design your joint to remove as much peel force as possible.

Posted by Abarmettler, ,

•

Advice | (0) Comments • Permalink

Page 2 of 4 pages < 1

2 3 4 >